VELOCITY. VERSATILITY. VALUE.

The world's premier automated programming system

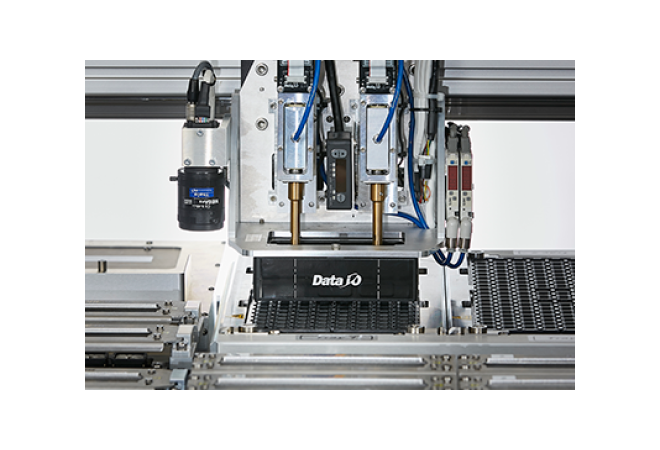

The PSV7000 is designed for speed and accuracy, offering high throughput, excellent uptime, flexibility, and quick changeovers to handle complex tasks required in the ROM copy process.

Key Features

Productivity and Scalability

Handler Throughput : 2,000 per hour

Handling Method : Dual vacuum nozzles

Handling Precision : ± .001mm

Handling Size

- Minimum : 1.5mm x 1.5mm

- Maximum : 32mm x 32mm

Programmer (LumenX) : Expandable up to 112 sites

Material Input/Output System Options

Supported Packages

: PLCC, SOIC, SON, WSON, SSOP,

CSP, BGA, uBGA, FPGA, QFP, TQFP, TSOP, PoP,

DIP, WLCSP, CSP

Auto Tray Feeder : JEDEC standard, 20 trays

Reel Feeder : 8mm to 56mm

Reel Packer : 8mm to 56mm

Tube Feeding and Packing Machines

Fiber Laser Marking System

3D Vision Camera

Reliability

High-Intensity Connector (HIC) Adapter designed for optimum quality and production

AH700 Intelligent System manages all aspects of production

PSV5000 and PSV7000 dedicated PNP head, developed by Data I/O

Integrated On-The-Fly Vision System in the head unit

Most reliable FlashCOREIII programming engine globally

LumenX programming engine designed for high-capacity memory

Cost Efficiency

Up to 50% cost reduction per memory unit

Minimized workforce requirements

Zero human error occurrence

Adapter compatibility across all Data I/O equipment

PSV7000: All components are selectable/removable

OPTION

I/O Media Options

Reel Feeder : Supports 8mm to 56mm

Reel Packer : Adjustable for 8mm to 56mm, capable of rewinding empty carrier tapes

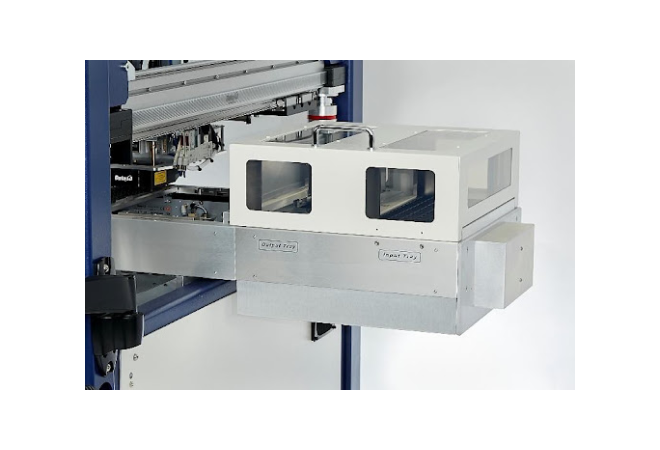

Dual Tray Feeder In/Out : Supports up to 20 JEDEC trays

Manual Tray : Operable without special tools, supports up to 2 manual trays

Tube Feeding/Packing Machine : Motor control for tube feeding and packing

Marking Options

Laser Marking System : High precision, supports simultaneous marking of two memories

Ink Dot Marking System : Supports ink dot marking on components sized 4x4mm

Ink Marking System : Supports various ink markings including letters and numbers

Inspection Features

3D Vision System : Precise 3D measurement up to 7 microns for components like QFP, TSOP, J-Lead, BGA, CSP

2D Reel Packing Vision System : Inspects laser marks and the orientation of memories during reel packing

Additional Options

Ionizer : Neutralizes charged surfaces by continuously generating positive and negative ions throughout the workspace

NexTeach Pro : Simplifies the teaching process with one-touch button operation for XYZR measurements and coordinate automation

Barcode Scanner : Minimizes operator errors by selecting the correct programming operation using a barcode scanner

SentriX Security Service : Provides security services for protecting IoT products

Additional Services : Server serial numbering, MES integration, command-line interface

Laser Marking System

High precision, supports simultaneous marking of two memories

3D Vision System

Accurately measures up to 7 microns for components like QFP, TSOP, J-Lead, BGA, CSP

2D Reel Packing Vision System

Inspects laser marks and memory orientation during reel packing

Ionizer

Neutralizes charged surfaces throughout the workspace by continuously generating ions

NEXT Teach Pro

Simplifies the teaching process with automated measurements and coordinate settings via a one-touch button (XYZR)

Ink Marking System

Supports a variety of ink markings, including letters and numbers

Tube Feeding/Packing Machine

Provides motor control for tube feeding and packing support

Dual Tray Feeder In/Out

Supports up to 20 JEDEC trays

Ink Dot Marking System

Supports ink dot marking for parts sized 4x4mm

Video

PSV7000 Introductory Video

PSV7000 NexTeach Pro Feature Explanation

PSV7000 2D Reel Packing Vision System Video

PSV7000 Laser Marking Video

PSV7000 3D Vision System Video

PSV7000 Ionizer Video