Provides measurement and inspection solutions necessary for functional testing of automotive electronic parts.

Customer Specification-based Functional Testing

User-Friendly UI

Editable Test Sequences with Proprietary Software

Modular System for Improved Maintainability

Production Product Management System with Reporting Function: Improves product quality and simplifies data trace management.

Stores data in the database to enhance product quality through traceability and quality assurance, and improves production efficiency by remotely monitoring the product status and other parameters.

Enables equipment operation monitoring for diagnosing equipment anomalies.

Customized Optimal Function Test System Based on Specification Analysis

Low Power, Low Noise System Implementation from Initial Design Stage

Eco-Friendly PCB Assembly Tester

(Battery Management System)

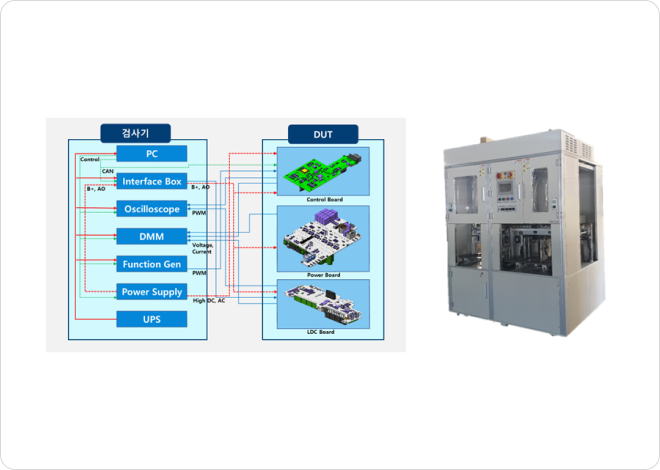

Purpose

Comprehensive testing for production lines of ICCU Control, Power, LDC Board, PIM (Control, Gate, EPS).

Functions

Control B/D: Power testing, ADC, Digital In/Out signals, PWM check, ROM writing.

Power B/D: Relay operation, SMPS operation, input voltage sensing.

LDC B/D: PWM driving and output verification.

Gate B/D: Power testing, FET operation check, Fault operation verification, Safety confirmation.

DPS B/D: HVDC and EPS operation verification, Fuse operation check.

BMS PCB Assembly Tester

(Battery Management System)

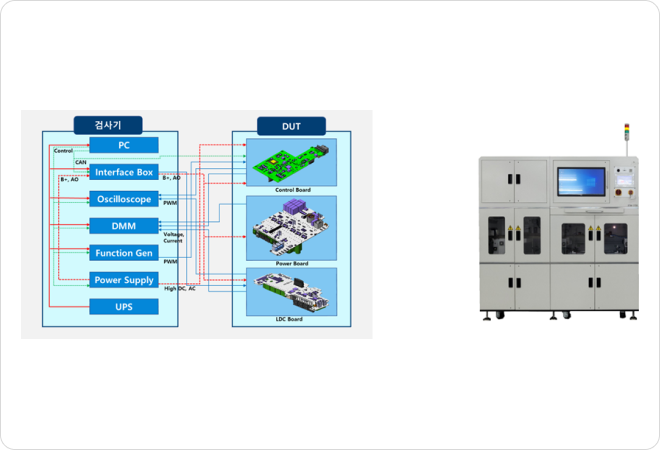

Purpose

Comprehensive testing/inspection of the BMS PCB production line.

Functions

BMU: Calibration, ADC, Relay operation, overcharge sensing, overcharge protection circuit verification.

CMU: Diagnosis, cell voltage sensing, cell balancing operation, temperature sensing, cell voltage line discontinuity, communication verification.